During the last years, consumers’ demand for “safe” food, including organic, is skyrocketing; thus, producers, manufacturers, sellers and end-users are often struggling to verify the accuracy of data across the whole supply chain of products (from farm to fork). Yet, consumers, especially within such niche markets, like organic food, are increasingly willing to pay for products that provide this information. To date, solutions have revolved around EU certifications and regulations, both of which add costs, are hard to enforce, create everlasting bureaucratic processes, and finally can be confusing to consumers. The challenge here is to obviate the need for a central trusted intermediary and instead develop a decentralised process that, without the need of intermediaries, achieves the same or better (in terms of accuracy, trust, evidence, complexity) functionality as today solutions. In this particular agricultural supply chain scenario, all interested stakeholders will be able to receive information about the conditions under which the products have been cultivated, stored and transported during their entire lifetime. This use case elicits requirements from real supply chain business processes in the agri-food sector that are involved in cultivating, tracking, tracing and selling of perishable goods. For the purposes of FISHY and in line with their expertise and interest, the FISHY partners involved in the F2F use case will offer:

- The Cooperative Winery of Nemea, as a subcontractor of SYN, will offer: (i) 20 hectares of vineyards, (ii) indoor stainless-steel tanks for wine storage, (iii) 3 production lines for wine bottling,

- SYN will offer precision agriculture and smart irrigation services through 10 SynField devices, equipped with totally more than 25 sensors to collect environmental data (soil moisture, air humidity, temperature, rainfall, wind direction and speed) as well as sensors for the management of irrigation and water consumption.

- OPT will provide its integrated system solution related to warehouse automation and logistics, focusing on traceability control, via its product, known as Aberon Trace Control, already installed in many enterprises storing and selling perishable products.

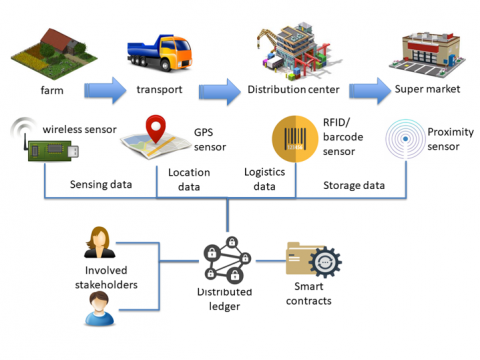

The left figure illustrates the life cycle of agri-food products, from their production to consumption point. Such life cycle is quite complex and involves a large number of actors and services and may generate a vast amount of data. For example, inside the farm, a perishable product could generate large volumes of related data (e.g., environmental conditions, utilization of fertilizers, date of plantation and harvest, water resources spent).

During transportation, data related to the preservation conditions (refrigerator temperature and humidity), shipment details and truck route (GPS data) until final destination can be traced and stored in a distributed ledger, excluding the possibility of non-repudiation. Additionally, data can be created in other intermediary places, such as distribution centers, keeping data with respect to warehouse conditions, final destination, responsible employee, etc. Finally, all the data can be processed, and made available to consumers in the supermarkets. Finally, within the Farm to Fork use case, the following beyond state-of-the-art tools and technologies will be integrated and validated:

- Tailored solution for Farm to Fork use case.

- Enrich existing framework supporting at least two interledger technologies.

- Integrate secure trade mechanisms on top of DLTs.

- Develop auditing mechanism to safeguard accountability based on evidence and not only trust.